Dupont Thermal Hoods

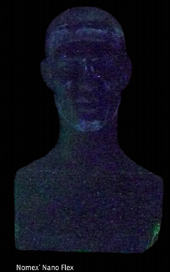

Nomex® Nano Flex

Integrating Nomex® Nano Flex with hood’s composite structure provides improved particle barrier protection in the neckline and upper jaw – the most vulnerable and least protected parts, resulting in up to a 4X increase in particle barrier efficiency.

| Results | Aerosol Mass (µm) | |||

|---|---|---|---|---|

| Sample Number | Head Form 1 No Barrier | Head Form 2 No Barrier | Head Form 3 No Barrier | Head Form 4 With Barrier |

| 1 | 4.45 | BDL* | 6.38 | BDL |

| 2 | 22.27 | BDL | 18.50 | BDL |

| 3 | 4.77 | BDL | 13.45 | BDL |

| 4 | 22.86 | BDL | 18.67 | BDL |

| Sum of Four Head Samples | 54.35 | n/a | 57.00 | n/a |

| Exterior of Helmet Face Shield | 34.66 | 93.72 | 58.16 | 66.32 |

| *BDL - Below Minimum Detection Limit. MDL = 0.18µm | ||||

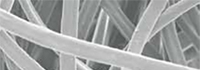

Nomex® Nano Flex is an elastic, air permeable, heat resistant, continuous polymer fiber based non-woven material with low bulk density used in hood applications.

Nomex® Nano Flex creates a barrier that can help dramatically reduced particle penetration.

Filtration efficiency,

% at most penetrating particle size

% at most penetrating particle size